Title 40 CFR Part

191

Subparts B and C

Compliance Recertification

Application

for the

Waste Isolation Pilot Plant

Appendix

PA-2009

Performance Assessment

United States

Department of Energy

Waste Isolation Pilot Plant

Carlsbad Field

Office

Carlsbad, New Mexico

Appendix PA-2009

Performance Assessment

PA-2.0 Overview and Conceptual Structure of the PA

PA-2.1 Overview of Performance Assessment

PA-2.1.1 Changes in the CRA-2009 PA

PA-2.1.2 Conceptual Basis for PA

PA-2.1.3 Undisturbed Repository Performance

PA-2.1.4 Disturbed Repository Performance

PA-2.1.4.1 Cuttings and Cavings

PA-2.1.4.4 Mobilization of Actinides in Repository Brine

PA-2.1.4.5 Long-Term Brine Flow up an Intrusion Borehole

PA-2.1.4.6 Groundwater Flow in the Culebra

PA-2.1.4.7 Actinide Transport in the Culebra

PA-2.1.4.8 Intrusion Scenarios

PA-2.1.5 Compliance Demonstration Method

PA-2.2 Conceptual Structure of the PA

PA-2.2.1 Regulatory Requirements

PA-2.2.2 Probabilistic Characterization of Different Futures

PA-2.2.3 Estimation of Releases

PA-2.2.4 Probabilistic Characterization of Parameter Uncertainty

PA-2.3.1 Identification and Screening of FEPs

PA-2.3.2 Scenario Development and Selection

PA-2.3.2.1 Undisturbed Repository Performance

PA-2.3.2.2 Disturbed Repository Performance

PA-2.3.2.2.1 Disturbed Repository M Scenario

PA-2.3.2.2.2 Disturbed Repository E Scenario

PA-2.3.2.2.5 The E1E2 Scenario

PA-2.3.2.3 Disturbed Repository ME Scenario

PA-2.3.2.4 Scenarios Retained for Consequence Analysis

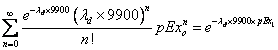

PA-2.3.3 Calculation of Scenario Consequences

PA-3.0 Probabilistic Characterization of Futures

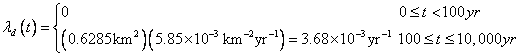

PA-3.4 Penetration of Excavated/Nonexcavated Area

PA-3.6 Penetration of Pressurized Brine

PA-3.10 Scenarios and Scenario Probabilities

PA-4.1 Results for Specific Futures

PA-4.2 Two-Phase Flow: BRAGFLO

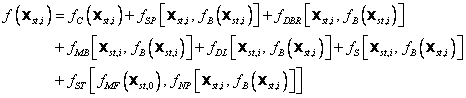

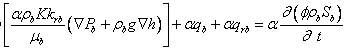

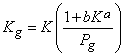

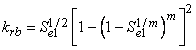

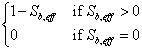

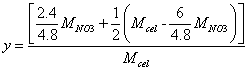

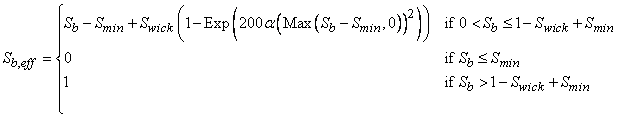

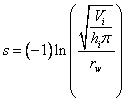

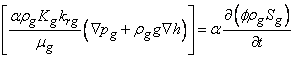

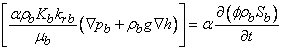

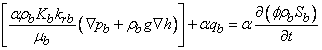

PA-4.2.1 Mathematical Description

PA-4.2.3 Creep Closure of Repository

PA-4.2.4 Fracturing of MBs and DRZ

PA-4.2.6 Capillary Action in the Waste

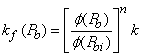

PA-4.2.8 Option D Panel Closures

PA-4.2.8.1 Panel Closure Concrete

PA-4.2.8.2 Panel Closure Abutment with MBs

PA-4.2.8.3 DRZ Above the Panel Closure

PA-4.2.8.4 Empty Drift and Explosion Wall Materials

PA-4.2.10 Castile Brine Reservoir

PA-4.2.12 Gas and Brine Flow across Specified Boundaries

PA-4.2.13 Additional Information

PA-4.3 Radionuclide Transport in the Salado: NUTS

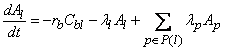

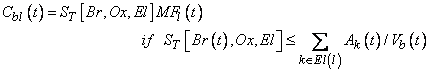

PA-4.3.1 Mathematical Description

PA-4.3.2 Calculation of Maximum Concentration ST( Br, Ox, El)

PA-4.3.3 Radionuclides Transported

PA-4.3.4 NUTS Tracer Calculations

PA-4.3.5 NUTS Transport Calculations

PA-4.3.7 Additional Information

PA-4.4 Radionuclide Transport in the Salado: PANEL

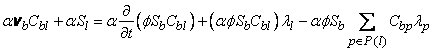

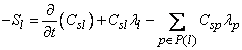

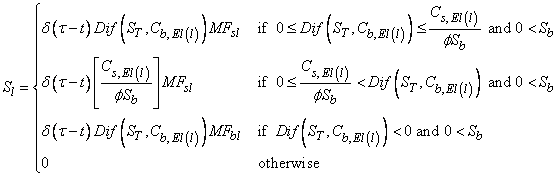

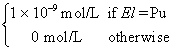

PA-4.4.1 Mathematical Description

PA-4.4.4 Additional Information

PA-4.5 Cuttings and Cavings to Surface: CUTTINGS_S

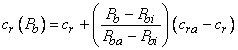

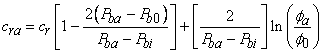

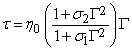

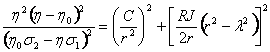

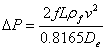

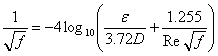

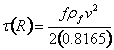

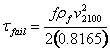

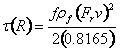

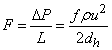

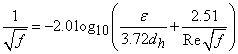

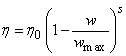

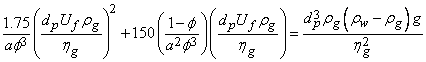

PA-4.5.2.2 Turbulent Flow Model

PA-4.5.3 Additional Information

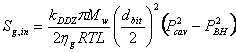

PA-4.6 Spallings to Surface: DRSPALL and CUTTINGS_S

PA-4.6.1 Summary of Assumptions

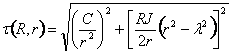

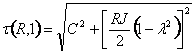

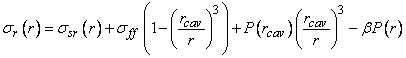

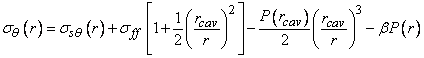

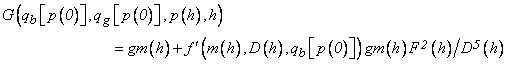

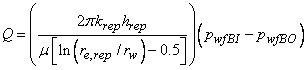

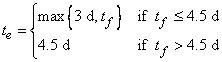

PA-4.6.2.1 Wellbore Flow Model

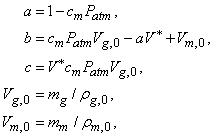

PA-4.6.2.1.1 Wellbore Initial Conditions

PA-4.6.2.1.2 Wellbore Boundary Conditions

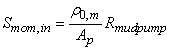

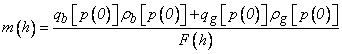

PA-4.6.2.2 Repository Flow Model

PA-4.6.2.3 Wellbore to Repository Coupling

PA-4.6.2.3.1 Flow Prior to Penetration

PA-4.6.2.3.2 Flow After Penetration

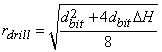

PA-4.6.2.3.3 Cavity Volume After Penetration

PA-4.6.2.3.5 Waste Fluidization

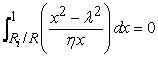

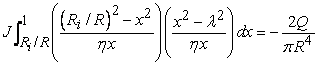

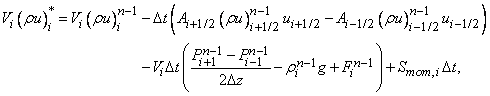

PA-4.6.3.1 Numerical Method—Wellbore

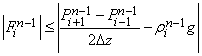

PA-4.6.3.2 Numerical Method—Repository

PA-4.6.3.3 Numerical Method—Wellbore to Repository Coupling

PA-4.6.5 Additional Information

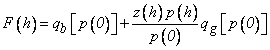

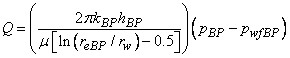

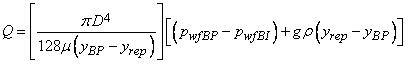

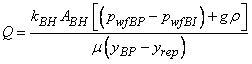

PA-4.7 DBR to Surface: BRAGFLO

PA-4.7.1 Overview of Conceptual Model

PA-4.7.2 Linkage to Two-Phase Flow Calculation

PA-4.7.3 Conceptual Representation for Flow Rate rDBR(t)

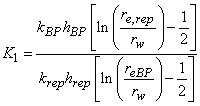

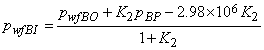

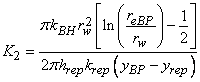

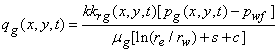

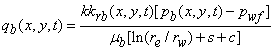

PA-4.7.4 Determination of Productivity Index Jp

PA-4.7.5 Determination of Waste Panel Pressure pw( t) and DBR

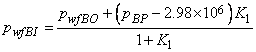

PA-4.7.6 Boundary Value Pressure pwf

PA-4.7.7 Boundary Value Pressure pwE1

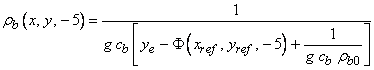

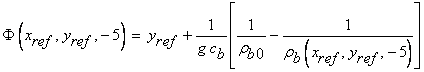

PA-4.7.7.1 Solution for Open Borehole

PA-4.7.7.2 Solution for Sand-Filled Borehole

PA-4.7.10 Additional Information

PA-4.8 Groundwater Flow in the Culebra Dolomite

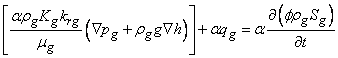

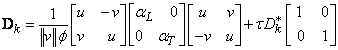

PA-4.8.1 Mathematical Description

PA-4.8.3 Computational Grids and Boundary Value Conditions

PA-4.8.5 Additional Information

PA-4.9 Radionuclide Transport in the Culebra Dolomite

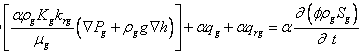

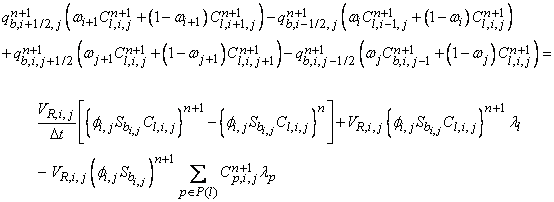

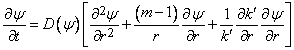

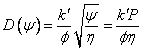

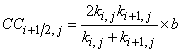

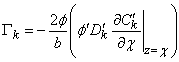

PA-4.9.1 Mathematical Description

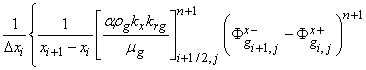

PA-4.9.1.1 Advective Transport in Fractures

PA-4.9.1.2 Diffusive Transport in the Matrix

PA-4.9.1.3Coupling Between Fracture and Matrix Equations

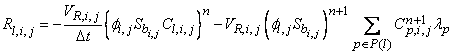

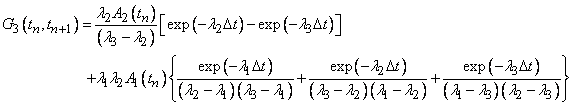

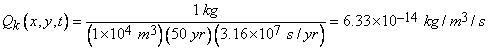

PA-4.9.1.5 Cumulative Releases

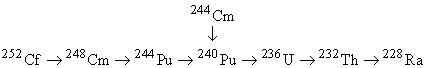

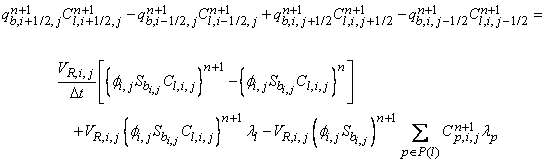

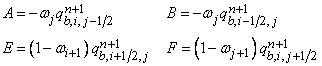

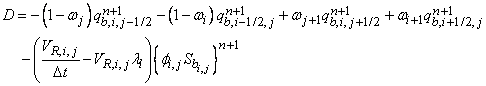

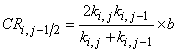

PA-4.9.2.1 Discretization of Fracture Domain

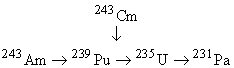

PA-4.9.2.2 Discretization of Matrix Equation

PA-4.9.2.3 Fracture-Matrix Coupling

PA-4.9.2.4 Cumulative Releases

PA-4.9.3 Additional Information

PA-5.0 Probabilistic Characterization of Subjective Uncertainty

PA-5.2 Variables Included for Subjective Uncertainty

PA-5.4 Correlations and Dependencies

PA-5.5 Separation of Aleatory and Epistemic Uncertainty

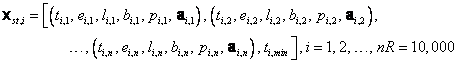

PA-6.0 Computational Procedures

PA-6.2 Sample Size for Incorporation of Subjective Uncertainty

PA-6.3 Statistical Confidence on Mean CCDF

PA-6.4 Generation of Latin Hypercube Samples

PA-6.5 Generation of Individual Futures

PA-6.7 Mechanistic Calculations

PA-6.7.5 CUTTINGS_S Calculations

PA-6.7.6 BRAGFLO Calculations for DBR Volumes

PA-6.7.8 SECOTP2D Calculations

PA-6.8.2.1 Construction of Cuttings and Cavings Releases

PA-6.8.2.2 Construction of Spallings Releases

PA-6.8.2.3 Construction of DBRs

PA-6.8.3 Radionuclide Transport Through the Culebra

PA-6.8.4 Determining Initial Conditions for Direct and Transport Releases

PA-6.8.4.1 Determining Repository and Panel Conditions

PA-6.8.4.2 Determining Distance from Previous Intrusions

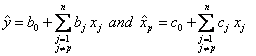

PA-6.9.3 Stepwise Regression Analysis

PA-7.0 Results for the Undisturbed Repository

PA-7.1.1 Pressure in the Repository

PA-7.1.2 Brine Saturation in the Waste

PA-7.1.3 Brine Flow Out of the Repository

PA-7.2.1 Radionuclide Transport to the Culebra

PA-7.2.2 Radionuclide Transport to the Land Withdrawal Boundary

PA-8.0 Results for a Disturbed Repository

PA-8.3.1 Pressure in the Repository

PA-8.3.3 Brine Flow out of the Repository

PA-8.4.1 Radionuclide Source Term

PA-8.4.2 Transport through MBs and Shaft

PA-8.4.3 Transport to the Culebra

PA-8.4.3.1 Single Intrusion Scenarios

PA-8.4.3.2 Multiple Intrusion Scenario

PA-8.4.4 Transport Through the Culebra

PA-8.4.4.1 Partial Mining Results

PA-8.4.4.2 Full Mining Results

Figure PA-1. Overall Mean CCDFs for Total Normalized Releases: CRA-2009 PA and CRA-2004 PABC

Figure PA-2. Computational Models Used in PA

Figure PA-3. Construction of the CCDF Specified in 40 CFR Part 191 Subpart B

Figure PA-4. Distribution of CCDFs Resulting from Possible Values for the Sampled Parameters

Figure PA-6. Example CCDF Distribution From CRA-2009 PA (Replicate 1)

Figure PA-7. Logic Diagram for Scenario Analysis

Figure PA-8. Conceptual Release Pathways for the UP Scenario

Figure PA-9. Conceptual Release Pathways for the Disturbed Repository M Scenario

Figure PA-10. Conceptual Release Pathways for the Disturbed Repository Deep Drilling E2 Scenario

Figure PA-11. Conceptual Release Pathways for the Disturbed Repository Deep Drilling E1 Scenario

Figure PA-12. Conceptual Release Pathways for the Disturbed Repository Deep Drilling E1E2 Scenario

Figure PA-13. CDF for Time Between Drilling Intrusions

Figure PA-14. Discretized Locations for Drilling Intrusions

Figure PA-15. Computational Grid Used in BRAGFLO for PA

Figure PA-16. Definition of Element Depth in BRAGFLO Grid

Figure PA-17. Identification of Individual Cells in BRAGFLO Grid

Figure PA-19. Schematic Side View of Option D Panel Closure

Figure PA-20. Representation of Option D Panel Closures in the BRAGFLO Grid

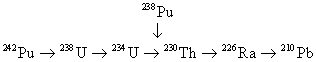

Figure PA-21. Selecting Radionuclides for the Release Pathways Conceptualized by PA

Figure PA-22. Detail of Rotary Drill String Adjacent to Drill Bit

Figure PA-23. Schematic Diagram of the Flow Geometry Prior to Repository Penetration

Figure PA-24. Schematic Diagram of the Flow Geometry After Repository Penetration

Figure PA-25. Effective Wellbore Flow Geometry Before Bit Penetration

Figure PA-26. Effective Wellbore Flow Geometry After Bit Penetration

Figure PA-27. Finite-Difference Zoning for Wellbore

Figure PA-28. DBR Grid Used in PA

Figure PA-29. Assignment of Initial Conditions for DBR Calculation

Figure PA-30. Borehole Representation Used for Poettmann-Carpenter Correlation

Figure PA-31. Areas of Potash Mining in the McNutt Potash Zone

Figure PA-33. Boundary Conditions Used for Simulations of Brine Flow in the Culebra

Figure PA-34. Finite-Difference Grid Showing Cell Index Numbering Convention Used by MODFLOW

Figure PA-35. Parallel-Plate, Dual-Porosity Conceptualization

Figure PA-36. Schematic of Finite-Volume Staggered Mesh Showing Internal and Ghost Cells

Figure PA-37. Illustration of Stretched Grid Used for Matrix Domain Discretization

Figure PA-38. Correlation Between S_HALITE:PRMX_LOG and S_HALITE:COMP_RCK

Figure PA-39. Correlation between CASTILLER:PRMX_LOG and CASTILLER:COMP_RCK

Figure PA-40. Dependency between WAS_AREA:GRATMICI and WAS_AREA:GRATMICH

Figure PA-41. Logic Diagram for Determining the Intrusion Type

Figure PA-42. Processing of Input Data to Produce CCDFs

Figure PA-43. Pressure in the Waste Panel Region, Replicate R1, Scenario S1, CRA-2009 PA

Figure PA-45. Brine Saturation in the Waste Panel Region, Replicate R1, Scenario S1, CRA-2009 PA

Figure PA-47. Brine Flow Away From the Repository, Replicate R1, Scenario S1, CRA-2009 PA

Figure PA-48. Brine Flow via All MBs Across the LWB, Replicate R1, Scenario S1, CRA-2009 PA

Figure PA-50. Pressure in the Waste Panel Region for Replicate R1, Scenario S2, CRA-2009 PA

Figure PA-51. Pressure in the Waste Panel Region for Replicate R1, Scenario S4, CRA-2009 PA

Figure PA-54. Brine Saturation in the Waste Panel Region for Replicate R1, Scenario S2, CRA-2009 PA

Figure PA-55. Brine Saturation in the Waste Panel Region for Replicate R1, Scenario S4, CRA-2009 PA

Figure PA-58. Total Cumulative Brine Outflow in Replicate R1, Scenario S2, CRA-2009 PA

Figure PA-59. Brine Flow via All MBs Across the LWB in Replicate R1, Scenario S2, CRA-2009 PA

Figure PA-60. Total Cumulative Brine Outflow in Replicate R1, Scenario S4, CRA-2009 PA

Figure PA-61. Brine Flow via All MBs Across the LWB in Replicate R1, Scenario S4, CRA-2009 PA

Figure PA-64. Total Mobilized Concentrations in Salado Brine, Replicate R1, CRA-2009 PA

Figure PA-65. Total Mobilized Concentrations in Castile Brine, Replicate R1, CRA-2009 PA

Figure PA-66. Cumulative Normalized Release to the Culebra, Scenario S2, CRA-2009 PA

Figure PA-67. Cumulative Normalized Release to the Culebra, Scenario S3, CRA-2009 PA

Figure PA-68. Cumulative Normalized Release to the Culebra, Scenario S4, CRA-2009 PA

Figure PA-69. Cumulative Normalized Release to the Culebra, Scenario S5, CRA-2009 PA

Figure PA-70. Cumulative Normalized Release to the Culebra, Replicate R1, Scenario S6, CRA-2009 PA

Figure PA-71. Scatterplot of Waste Particle Diameter Versus Spallings Volume, CRA-2009 PA

Figure PA-72. Scatterplot of Waste Permeability Versus Spallings Volume, CRA-2009 PA

Figure PA-74. Overall Mean CCDFs for Cuttings and Cavings Releases: CRA-2009 PA and CRA-2004 PABC

Figure PA-75. Overall Mean CCDFs for Spallings Releases: CRA-2009 PA and CRA 2004 PABC

Figure PA-76. Overall Mean CCDFs for DBRs: CRA-2009 PA and CRA-2004 PABC

Figure PA-78. The Preponderance and Distribution of Zeros Can Control the Regression

Figure PA-79. Total Normalized Releases, Replicates R1, R2, and R3, CRA-2009 PA

Figure PA-80. Confidence Interval on Overall Mean CCDF for Total Normalized Releases, CRA-2009 PA

Figure PA-81. Mean CCDFs for Components of Total Normalized Releases, Replicate R1, CRA-2009 PA

Figure PA-82. Mean CCDFs for Components of Total Normalized Releases, Replicate R2, CRA-2009 PA

Figure PA-83. Mean CCDFs for Components of Total Normalized Releases, Replicate R3, CRA-2009 PA

Figure PA-84. Overall Mean CCDFs for Total Normalized Releases: CRA-2009 PA and CRA-2004 PABC

Table PA-1. WIPP Project Changes and Cross References

Table PA-3. Parameter Values Used in Representation of Two-Phase Flow

Table PA-4. Models for Relative Permeability and Capillary Pressure in Two-Phase Flow

Table PA-5. Initial Conditions in the Rustler

Table PA-7. Permeabilities for Drilling Intrusions Through the Repository

Table PA-8. Boundary Value Conditions for Pg and Pb

Table PA-9. Auxiliary Dirichlet Conditions for Sg and Pb

Table PA-10. Calculated Values for Dissolved Solubility (see Appendix SOTERM-2009, Table SOTERM-16)

Table PA-13. Combination of Radionuclides for Transport

Table PA-14. Initial and Boundary Conditions for Cbl( x, y, t) and Csl( x, y, t)

Table PA-15. Uncertain Parameters in the DRSPALL Calculations

Table PA-16. Initial Porosity in the DBR Calculation

Table PA-17. Boundary Conditions for pb and Sg in DBR Calculations

Table PA-18. Radionuclide Culebra Transport Diffusion Coefficients

Table PA-19. Variables Representing Epistemic Uncertainty in the CRA-2009 PA

Table PA-20. Sampled Parameters Added Since the CRA-2004 PA

Table PA-21. Sampled Parameters Removed Since the CRA-2004 PA

Table PA-24. Algorithm to Generate a Single Future

Table PA-25. BRAGFLO Scenarios in the CRA-2009 PA

Table PA-26. NUTS Release Calculations in the CRA-2009 PA

Table PA-27. CUTTINGS_S Release Calculations in the CRA-2009 PA

Table PA-28. MODFLOW Scenarios in the CRA-2009 PA

Table PA-29. SECOTP2D Scenarios in the CRA-2004 PA

Table PA-32. CRA-2009 PA Cuttings and Cavings Area Statistics

Table PA-33. CRA-2009 PA Spallings Volume Statistics

% percent

AIC active institutional control

An actinide

BRAGFLO BRine And Gas FLOw computer code

C Celsius

CCA Compliance Certification Application

CCDF complementary cumulative distribution function

CDF cumulative distribution function

CFR Code of Federal Regulations

CH-TRU contact-handled transuranic

Ci curies

CL Confidence Limit

CPR cellulosic, plastic, and rubber

CRA Compliance Recertification Application

DBR direct brine release

DDZ drilling damaged zone

DOE U.S. Department of Energy

DP disturbed repository performance

DRZ disturbed rock zone

E deep drilling scenario

EPA U.S. Environmental Protection Agency

ERDA U.S.Energy Research and Development Administration

FEP feature, event, and process

FMT Fracture-Matrix Transport

FVW fraction of excavated repository volume occupied by waste

gal gallon

GWB Generic Weep Brine

in inch

J Joule

K Kelvin

Kd distribution coefficient

kg kilogram

km kilometer

km2 square kilometers

L liter

LHS Latin hypercube sampling

LWB land withdrawal boundary

M mining scenario

m meter

m2 square meters

m3 cubic meters

MB marker bed

ME mining and drilling scenario

mi miles

mol mole

MPa megapascal

MTHM metric tons of heavy metal

MWd megawatt-days

N Newton

Pa Pascal

PA performance assessment

PABC performance assessment baseline calculation

PAVT Performance Assessment Verification Test

PCC partial correlation coefficient

PCS panel closure system

PDE partial differential equation

PDF probability distribution function

PIC passive institutional control

PRCC partial rank correlation coefficient

RH-TRU remote-handled transuranic

RKS Redlich-Kwong-Soave

RoR Rest of Repository

s second

s2 seconds squared

SCF/d standard cubic feet per day

SMC Salado Mass Concrete

SNL Sandia National Laboratories

SRC standardized regression coefficient

T field transmissivity field

TRU transuranic

TVD Total Variation Diminishing

UP undisturbed repository performance

WIPP Waste Isolation Pilot Plant

yr year

Al aluminum

Am americium

C carbon

C6H10O5 generic formula for CPR

Ca calcium

CH4 methane

Cm curium

CO2 carbon dioxide

Cr chromium

Cs cesium

Fe iron

H2 hydrogen gas

H2O water

H2S hydrogen sulfide

I iodine

Mg magnesium

Mg(OH)2 brucite

Mg5(CO3)4(OH)2×4H2O hydromagnesite (5424)

MgO magnesium oxide, or periclase

Mn manganese

Ni nickel

NO3 - nitrate

Np neptunium

Pb lead

Pm promethium

Pu plutonium

Ra radium

Sn tin

SO4 sulfate

SO42- sulfate ion

Sr strontium

Tc technetium

Th thorium

U uranium

V vanadium

This appendix presents the mathematical models used to evaluate performance of the Waste Isolation Pilot Plant (WIPP) disposal system and the results of these models for the 2009 Compliance Recertification Application (CRA-2009) Performance Assessment (PA). The term PA signifies an analysis that (1) identifies the processes and events that might affect the disposal system; (2) examines the effects of these processes and events on the performance of the disposal system; and (3) estimates the cumulative releases of radionuclides, considering the associated uncertainties, caused by all significant processes and events (40 CFR § 191.12 [U.S. Environmental Protection Agency 1993]). PA is designed to address three primary questions about the WIPP:

Q1: What processes and events that might affect the disposal system could take place at the WIPP site over the next 10,000 years?

Q2: How likely are the various processes and events that might affect the disposal system to take place at the WIPP site over the next 10,000 years?

Q3: What are the consequences of the various processes and events that might affect the disposal system that could take place at the WIPP site over the next 10,000 years?

In addition, accounting for uncertainty in the parameters of the PA models leads to a further question:

Q4: How much confidence should be placed in answers to the first three questions?

These questions give rise to a methodology for quantifying the probability distribution of possible radionuclide releases from the WIPP repository over the next 10,000 years and characterizing the uncertainty in that distribution due to imperfect knowledge about the parameters contained in the models used to predict releases. The containment requirements of 40 CFR § 191.13 require this probabilistic methodology.

This appendix is organized as follows: Section PA-2.0 gives an overview and describes the overall conceptual structure of the CRA-2009 PA. The WIPP PA is designed to address the requirements of section 191.13, and thus involves three basic entities: (1) a probabilistic characterization of different futures that could occur at the WIPP site over the next 10,000 years, (2) models for both the physical processes that take place at the WIPP site and the estimation of potential radionuclide releases that may be associated with these processes, and (3) a probabilistic characterization of the uncertainty in the models and parameters that underlies the WIPP PA. Section PA-2.0 is supplemented by Appendix SCR-2009, which documents the results of the screening process for features, events, and processes (FEPs) that are retained in the conceptual models of repository performance.

Section PA-3.0 describes the probabilistic characterization of different futures. This characterization plays an important role in the construction of the complementary cumulative distribution function (CCDF) specified in section 191.13. Regulatory guidance and extensive review of the WIPP site identified exploratory drilling for natural resources and the mining of potash as the only significant disruptions at the WIPP site with the potential to affect radionuclide releases to the accessible environment. Section PA-3.0 summarizes the stochastic variables that represent future drilling and mining events in the PA. The results of the PA for CRA-2009, as documented in Section PA-7.0, Section PA-8.0, and Section PA-9.0 of this appendix, confirm that direct releases from drilling intrusions are the major contributors to radionuclide releases to the accessible environment.

Section PA-4.0 presents the mathematical models for both the physical processes that take place at the WIPP and the estimation of potential radionuclide releases. The mathematical models implement the conceptual models as prescribed in 40 CFR § 194.23 (2004), and permit the construction of the CCDF specified in section 191.13. Models presented in Section PA-4.0 include two-phase (i.e., gas and brine) flow in the vicinity of the repository; radionuclide transport in the Salado Formation (hereafter referred to as the Salado); releases to the surface at the time of a drilling intrusion due to cuttings, cavings, spallings, and direct brine releases (DBRs); brine flow in the Culebra Dolomite Member of the Rustler Formation (hereafter referred to as the Culebra); and radionuclide transport in the Culebra. Section PA-4.0 is supplemented by Appendices MASS-2009, TFIELD-2009, and PORSURF-2009. Appendix MASS-2009 discusses the modeling assumptions used in the WIPP PA. Appendix TFIELD-2009 discusses the generation of the transmissivity fields (T fields) used to model groundwater flow in the Culebra. Appendix PORSURF-2009 presents results from modeling the effects of excavated region closure, waste consolidation, and gas generation in the repository.

Section PA-5.0 discusses the probabilistic characterization of parameter uncertainty, and summarizes the uncertain variables incorporated into the CRA-2009 PA, the distributions assigned to these variables, and the correlations between variables. Section PA-5.0 is supplemented by Fox (2008) and Appendix SOTERM-2009. Fox (2008) catalogs the full set of parameters used in the CRA-2009 PA, previously referred to as the CCA Appendix PAR and the CRA-2004, Appendix PA, Attachment PAR. Appendix SOTERM-2009 describes the actinide (An) source term for the WIPP performance calculations, including the mobile concentrations of actinides that may be released from the repository in brine.

Section PA-6.0 summarizes the computational procedures used in the CRA-2009 PA, including sampling techniques (i.e., random and Latin hypercube sampling (LHS)); sample size, statistical confidence for mean CCDF, generation of sample, generation of individual futures, construction of CCDFs, calculations performed with the models discussed in Section PA-4.0, construction of releases for each future, and the sensitivity analysis techniques in use.

Section PA-7.0 presents the results of the PA for an undisturbed repository. Releases from the undisturbed repository are determined by radionuclide transport in brine flowing from the repository to the land withdrawal boundary (LWB) through the marker beds (MBs) or shafts. Releases in the undisturbed scenario are used to demonstrate compliance with the individual and groundwater protection requirements in 40 CFR Part 191 (40 CFR § 194.51 and 40 CFR § 194.52).

Section PA-8.0 presents PA results for a disturbed repository. As will be discussed in Section PA-2.3.1, the only future events and processes in the analysis of disturbed repository performance are those associated with mining and deep drilling. Release mechanisms include direct releases at the time of the intrusion via cuttings, cavings, spallings, and DBR, and long-term releases via radionuclide transport up abandoned boreholes to the Culebra and thence to the LWB.

Section PA-9.0 presents the set of CCDFs resulting from the CRA-2009 PA. This material supplements 40 CFR § 194.34, which demonstrates compliance with the containment requirements of section 191.13. Section PA-9.0 presents the most significant output variables from the PA models, accompanied by sensitivity analyses to determine which subjectively uncertain parameters are most influential in the uncertainty of PA results.

The overall structure of the CRA-2009 PA does not differ from that presented in the first WIPP Compliance Certification Application (CCA) (U.S. Department of Energy 1996), the CRA-2004 (U.S. Department of Energy 2004) or the CRA-2004 Performance Assessment Baseline Calculation (PABC) (Leigh et al. 2005). This recertification application appendix follows the approach used by Helton et al. (1998) to document the mathematical models used in the CCA PA and the results of that analysis. Much of the content of this appendix derives from Helton et al. (1998); these authors’ contributions are gratefully acknowledged.

Because of the amount and complexity of the material presented in Appendix PA-2009, an introductory summary is provided below, followed by detailed discussions of the topics in the remainder of this section, which is organized as follows:

Section PA-2.1 – Overview of PA and the results

Section PA-2.2 – The conceptual structure of the PA used to evaluate compliance with the containment requirements

Section PA-2.3 – The overall methodology used to develop FEPs, the screening methodology applied to the FEPs, the results of the screening process, and the development of the scenarios considered in the system-level consequence analysis

The U.S. Department of Energy (DOE) continues to use the same PA methodology as in the CCA and CRA-2004 because changes that have been made since the U.S. Environmental Protection Agency (EPA) certified WIPP do not impact PA methodology. A corresponding detailed presentation for the CRA-2004 PA methodology is provided in the CRA-2004, Chapter 6.0, Section 6.1, and a detailed presentation for the CRA-2004 PABC implementation is provided in Leigh et al. (2005). A corresponding detailed presentation for the CCA PA methodology is provided in Helton et al. (1998, Section 2).

A demonstration of future repository performance was required by the disposal standards in Part 191. The EPA required a PA to demonstrate that potential cumulative releases of radionuclides to the accessible environment over a 10,000-year period after disposal are less than specified limits based on the nature of the materials disposed (section 191.13). The PA is to determine the effects of all significant processes and events that may affect the disposal system, consider the associated uncertainties of the processes and events, and estimate the probable cumulative releases of radionuclides.

A PA was included in the CCA. This was the first demonstration of compliance by the DOE with the EPA’s disposal standards. The EPA required a verification PA based on the CCA PA that included revised parameters and distributions. This PA was termed the CCA Performance Assessment Verification Test (PAVT) (Trovoto 1997). The EPA based the original certification of the WIPP on the information in the CCA and the results of the CCA PAVT (U.S. Environmental Protection Agency 1998a). The CCA PAVT is documented in Sandia National Laboratories (SNL) 1997 and U.S. Department of Energy 1997.

The WIPP is required to be recertified every five years after first waste receipt (Public Law 02-579). A revised PA was included in the first recertification application in 2004. This PA is termed the CRA-2004 PA, and is documented in the CRA-2004, Chapter 6.0. The EPA again required a verification PA using revised modeling assumptions and parameters (Cotsworth 2005). This PA was termed the CRA-2004 PABC and was documented in Leigh et al. (2005).

As part of the five-year recertification cycle, a PA is included in the CRA-2009. The CRA-2009 PA is a culmination of the previous PAs and is not significantly different from the CRA-2004 PABC, as the methodologies, conceptual models, and assumptions have not changed. Updates to parameters and improvements to computer codes are incorporated in the CRA-2009.

A list of changes to PA since the CRA-2004 and citations for where they are discussed is shown in Table PA-1. In addition to the changes discussed in Table PA-1, the terminology used to describe uncertainty has been updated to reflect the usage now prevalent in the risk assessment literature. Previously, uncertainty in model parameters was referred to as “subjective uncertainty,” and that due to stochastic processes was referred to as “stochastic uncertainty.” In the years since these terms were first employed, these concepts have matured, and the term “epistemic uncertainty” is now used to describe uncertainty from lack of knowledge, while the term “aleatory uncertainty” now describes uncertainty due to natural variability, e.g. uncertainty arising from future events whose occurrence can be defined in terms of probabilities. In this text, the terms epistemic uncertainty and aleatory uncertainty are used in place of the terms subjective uncertainty and stochastic uncertainty, respectively.

Table PA-1. WIPP Project Changes and Cross References

|

WIPP Project Change |

Cross Reference |

|

CRA-2004 to CRA-2004 PABC Changesa |

|

|

Inventory Information |

|

|

An Solubility Values |

|

|

An Solubility Uncertainty Ranges |

Garner and Leigh 2005 |

|

Microbial Gas Generation Model |

|

|

Culebra T Fields Mining Modification |

|

|

Anhydrite Material Parameters |

|

|

SPALL Model Parameters |

|

|

CRA-2004 PABC to CRA-2009 Changesb |

|

|

DBR Maximum Duration Parameter |

|

|

Conditional Relationship Between Humid and Inundated Cellulosic, Plastic, or Rubber (CPR) Degradation Rates |

|

|

BRAGFLO Code Improvements |

|

|

Capillary Pressure and Relative Permeability Model |

Nemer and Clayton 2008 |

|

Drilling Rate |

|

|

Parameter Error Corrections · Emplaced CPR · Halite/Disturbed Rock Zone (DRZ) Parameter · Fraction of Repository Occupied by Waste · NUTS and DBR Calculation Input Files |

Nemer 2007a, Ismail 2007a, Dunagan 2007, Ismail 2007b, Clayton 2007 |

|

a See Leigh et al. 2005 for additional discussion of these changes and their implementation in the CRA-2004 PABC. b See Clayton et al. 2008 for additional discussions of these changes and their implementation in the CRA-2009 PA. |

|

From this assessment, the DOE has demonstrated that the WIPP continues to comply with the containment requirements of section 191.13. The containment requirements are stringent and state that the DOE must demonstrate a reasonable expectation that the probabilities of cumulative radionuclide releases from the disposal system during the 10,000 years following closure will fall below specified limits. The PA analyses supporting this determination must be quantitative and consider uncertainties caused by all significant processes and events that may affect the disposal system, including future inadvertent human intrusion into the repository. A quantitative PA is conducted using a series of loosely coupled computer models in which epistemic parameter uncertainties are addressed by a stratified Monte Carlo sampling procedure on selected input parameters, and uncertainties related to future intrusion events are addressed using simple random sampling.

As required by regulation, results of the PA are displayed as CCDFs showing the probability that cumulative radionuclide releases from the disposal system will exceed the values calculated for scenarios considered in the analysis. These CCDFs are calculated using reasonable and, in some cases, conservative conceptual models based on the scientific understanding of the disposal system’s behavior. Parameters used in these models are derived from experimental data, field observations, and relevant technical literature. Changes to the CCA and CRA-2004 parameters and models since the original certification have been incorporated into the CRA-2009 PA (Clayton 2008a). The overall mean CCDF continues to lie entirely below the specified limits, and the WIPP therefore continues to be in compliance with the containment requirements of 40 CFR Part 191 Subpart B (see Section PA-2.1.6). Sensitivity analysis of results shows that the location of the mean CCDF is dominated by radionuclide releases that could occur on the surface during an inadvertent penetration of the repository by a future drilling operation (Section PA-9.0). Releases of radionuclides to the accessible environment from transport in groundwater through the shaft seal systems and the subsurface geology are negligible, with or without human intrusion, and do not significantly contribute to the mean CCDF. No releases are predicted to occur at the ground surface in the absence of human intrusion. The natural and engineered barrier systems of the WIPP provide robust and effective containment of transuranic (TRU) waste, even if the repository is penetrated by multiple boreholes.

The foundations of PA are a thorough understanding of the disposal system and the possible future interactions of the repository, waste, and surrounding geology. The DOE’s confidence in the results of PA is based in part on the strength of the original research done during site characterization, experimental results used to develop and confirm parameters and models, and robustness of the facility design.

The progression of compliance applications document these aspects of PA leading up to the CRA-2009 PA (i.e., the CCA, the CCA PAVT [Sandia National Laboratories 1997 and U.S. Department of Energy 1997], the CRA-2004 PA, and the CRA-2004 PABC [Leigh et al. 2005]).

The interactions of the repository and waste with the geologic system, and the response of the disposal system to possible future inadvertent human intrusion, are described in Section PA-2.1.4.

An evaluation of undisturbed repository performance, which is defined to exclude human intrusion and unlikely disruptive natural events, is required by regulation (see 40 CFR § 191.15 and 40 CFR § 191.24). Evaluations of past and present natural geologic processes in the region indicate that none has the potential to breach the repository within 10,000 years (see the CCA, Appendix SCR, Section SCR.1). Disposal system behavior is dominated by the coupled processes of rock deformation surrounding the excavation, fluid flow, and waste degradation. Each of these processes can be described independently, but the extent to which they occur is affected by the others.

Rock deformation immediately around the repository begins as soon as excavation creates a disturbance in the stress field. Stress relief results in some degree of brittle fracturing and the formation of a DRZ, which surrounds excavations in all deep mines including the WIPP repository. For the WIPP, the DRZ is characterized by an increase in permeability and porosity, and it may ultimately extend a few meters (m) from the excavated region. Salt will also deform by creep processes resulting from deviatoric stress, causing the salt to move inward and fill voids. Salt creep will continue until deviatoric stress is dissipated and the system is once again at stress equilibrium (see the CRA-2004, Chapter 6.0, Section 6.4.3.1).

The ability of salt to creep, thereby healing fractures and filling porosity, is one of its fundamental advantages as a medium for geologic disposal of radioactive waste, and one reason it was recommended by the National Academy of Sciences (see the CCA, Chapter 1.0, Section 1.3). Salt creep provides the mechanism for crushed salt compaction in the shaft seal system, yielding properties approaching those of intact salt within 200 years (see the CCA, Appendix SEAL, Appendix D, Section D5.2). Salt creep will also cause the DRZ surrounding the shaft to heal rapidly around the concrete components of the seal system. In the absence of elevated gas pressure in the repository, salt creep would also substantially compact the waste and heal the DRZ around the disposal region. Fluid pressures can become large enough through the combined effect of salt creep reducing pore volumes, and gas generation from waste degradation processes, to maintain significant porosity (greater than 20%) within the disposal room throughout the performance period (see also the CRA-2004, Chapter 6.0, Section 6.4.3).

Characterization of the Salado indicates that fluid flow from the far field does not occur on time scales of interest in the absence of an artificially imposed hydraulic gradient (see the CRA-2004, Chapter 2.0, Section 2.1.3.4 for a description of Salado investigations). This lack of fluid flow is the second fundamental reason for choosing salt as a medium for geologic disposal of radioactive waste. Lack of fluid flow is a result of the extremely low permeability of evaporite rocks that make up the Salado. Excavating the repository has disturbed the natural hydraulic gradient and rock properties, resulting in fluid flow. Small quantities of interstitial brine present in the Salado move toward regions of low hydraulic potential, and brine seeps are observed in the underground repository. The slow flow of brine from halite into more permeable anhydrite MBs, and then through the DRZ into the repository, is expected to continue as long as the hydraulic potential within the repository is below that of the far field. The repository environment will also include gas, so the fluid flow must be modeled as a two-phase process. Initially, the gaseous phase will consist primarily of air trapped at the time of closure, although other gases may form from waste degradation. In the PA, the gaseous phase pressure will rise due to creep closure, gas generation, and brine inflow, creating the potential for flow from the excavated region (see also the CRA-2004, Chapter 6.0, Section 6.4.3.2).

An understanding of waste degradation processes indicates that the gaseous phase in fluid flow and the repository’s pressure history will be far more important than if the initial air were the only gas present. Waste degradation can generate significant additional gas by two processes (see also the CRA-2004, Chapter 6.0, Section 6.4.3.3 for historical perspective, and Leigh et al. 2005, Section 2.3 and Section 2.4 for changes):

1. The generation of hydrogen (H2) gas by anoxic corrosion of steels, other iron (Fe)-based alloys, and aluminum (Al) and Al-based alloys

2. The generation of carbon dioxide (CO2), hydrogen sulfide (H2S), and methane (CH4) by anaerobic microbial consumption of waste containing CPR materials

Coupling these gas-generation reactions to fluid-flow and salt-creep processes is complex. Gas generation will increase fluid pressure in the repository, thereby decreasing the hydraulic gradient and deviatoric stress between the far field and the excavated region and inhibiting the processes of brine inflow and salt creep. Anoxic corrosion will also consume brine as it breaks down water to oxidize steels and other Fe-based alloys and release H2. Thus, corrosion has the potential to be a self-limiting process, in that as it consumes all water in contact with steels and other Fe-based alloys, it will cease. Microbial reactions also require water, either in brine or the gaseous phase. It is assumed that microbial reactions will result in neither the consumption nor production of water.

The total volume of gas generated by corrosion and microbial consumption may be sufficient to result in repository pressures that approach lithostatic. Sustained pressures above lithostatic are not physically reasonable within the disposal system, because the more brittle anhydrite layers are expected to fracture if sufficient gas is present. The conceptual model implemented in the PA causes anhydrite MB permeability and porosity to increase rapidly as pore pressure approaches and exceeds lithostatic. This conceptual model for pressure-dependent fracturing approximates the hydraulic effect of pressure-induced fracturing and allows gas and brine to move more freely within the MBs at higher pressures (see the CRA-2004, Chapter 6.0, Section 6.4.5.2).

Overall, the behavior of the undisturbed disposal system will result in extremely effective isolation of the radioactive waste. Concrete, clay, and asphalt components of the shaft seal system will provide an immediate and effective barrier to fluid flow through the shafts, isolating the repository until salt creep has consolidated the compacted crushed salt components and permanently sealed the shafts. Around the shafts, the DRZ in halite layers will heal rapidly because the presence of the solid material within the shafts will provide rigid resistance to creep. The DRZ around the shaft, therefore, will not provide a continuous pathway for fluid flow (see the CRA-2004, Chapter 6.0, Section 6.4.4). Similarly, the panel closure will rigidly resist creep, leading to a build-up of compressive stress which in turn will cause a rapid elimination of the DRZ locally. In PA, it is conservatively assumed that the DRZ does not heal around either the disposal region or the operations and experimental regions, and pathways for fluid flow may exist indefinitely to the overlying and underlying anhydrite layers (e.g., MB 139 and Anhydrites A and B). Some quantity of brine will be present in the repository under most conditions and may contain actinides mobilized as both dissolved and colloidal species. Gas generation by corrosion and microbial degradation is expected to occur, and will result in elevated pressures within the repository. These pressures will not significantly exceed lithostatic because the more brittle anhydrite layers will fracture and provide a pathway for gas to leave the repository. Fracturing due to high gas pressures may enhance gas and brine migration from the repository, but gas transport will not contribute to the release of actinides from the disposal system. Brine flowing out of the waste disposal region through anhydrite layers may transport actinides as dissolved and colloidal species. However, the quantity of actinides that may reach the accessible environment boundary through the interbeds during undisturbed repository performance is insignificant and has no effect on the compliance determination. No migration of radionuclides is expected to occur vertically through the Salado (see Section PA-7.0, and Ismail and Garner 2008).

The WIPP PA is required by the performance standards to consider scenarios that include intrusions into the repository by inadvertent and intermittent drilling for resources. The probability of these intrusions is based on a future drilling rate. This rate was calculated using the method outlined in Section 33, which analyzes the past record of drilling events in the Delaware Basin. Active institutional controls (AICs) are assumed to prevent intrusion during the first 100 years after closure (40 CFR § 194.41). Passive institutional controls (PICs) were assumed in the CCA to effectively reduce the drilling rate by two orders of magnitude for the 600-year period following 100 years of active control. However, in certifying the WIPP, the EPA denied credit for the effectiveness of passive controls for 600 years (U.S. Environmental Protection Agency 1998a). Although the CRA-2009 PA does not include a reduced drilling intrusion rate to account for PICs, future PAs may do so. Future drilling practices are assumed to be the same as current practice, also consistent with regulatory criteria. These practices include the type and rate of drilling, emplacement of casing in boreholes, and the procedures implemented when boreholes are plugged and abandoned (see 40 CFR § 194.33).

Human intrusion by drilling may cause releases from the disposal system through five mechanisms:

1. Cuttings, which include material intersected by the rotary drilling bit

2. Cavings, which include material eroded from the borehole wall during drilling

3. Spallings, which include solid material carried into the borehole during rapid depressurization of the waste disposal region

4. DBRs, which include contaminated brine that may flow to the surface during drilling

5. Long-term brine releases, which include the contaminated brine that may flow through a borehole after it is abandoned

The first four mechanisms immediately follow an intrusion event and are collectively referred to as direct releases. The accessible environment boundary for these releases is the ground surface. The fifth mechanism, An transport by long-term groundwater flow, begins when concrete plugs are assumed to degrade in an abandoned borehole and may continue throughout the regulatory period. The accessible environment boundary for these releases is the lateral subsurface limit of the controlled area (CRA-2004, Chapter 6.0, Section 6.0.2.3).

Repository conditions prior to intrusion will be the same as those for undisturbed repository performance, and all processes active in undisturbed repository performance will continue to occur following intrusion. Because an intrusion provides a pathway for radionuclides to reach the ground surface and enter the geological units above the Salado, additional processes will occur that don’t in the undisturbed repository performance. These processes include the mobilization of radionuclides as dissolved and colloidal species in repository brine and groundwater flow, and subsequent An transport in the overlying units. Flow and transport in the Culebra are of particular interest because it is the most transmissive unit above the repository. Thus, the Culebra is a potential pathway for lateral migration of contaminated brine in the event of a drilling intrusion accompanied by significant flow up the intrusion borehole (see the CRA-2004, Chapter 6.0, Section 6.4.6.2).

In a rotary drilling operation, the volume of material brought to the surface as cuttings is calculated as the cylinder defined by the thickness of the unit and the diameter of the drill bit. The quantity of radionuclides released as cuttings is therefore a function of the activity of the intersected waste and the diameter of the intruding drill bit. The DOE uses a constant value of 0.31115 m (12.25 inches [in]), consistent with bits currently used at the WIPP depth in the Delaware Basin (see the CRA-2004, Chapter 6.0, Section 6.4.12.5). The intersected waste activity may vary depending on the type of waste intersected. The DOE considers random penetrations into remote-handled (RH) transuranic (TRU) (RH-TRU) waste and each of the 690 different waste streams (Leigh, Trone, and Fox 2005, Section 4.4) identified for contact-handled (CH) transuranic (TRU) (CH-TRU) waste (569 and 693 waste streams were used in the CCA and the CRA-2004, respectively; see the CRA-2004, Chapter 6.0, Section 6.0.2.3.1).

The volume of particulate material eroded from the borehole wall by the drilling fluids and brought to the surface as cavings may be affected by the drill bit diameter, effective shear resistance of the intruded material, speed of the drill bit, viscosity of the drilling fluid and rate at which it is circulated in the borehole, and other properties related to the drilling process. The most important of these parameters, after drill bit diameter, is the effective shear resistance of the intruded material (Leigh et al. 2005, Section 7.2). In the absence of data describing the reasonable and realistic future properties of degraded waste and magnesium oxide (MgO) backfill, the DOE used conservative parameter values based on the properties of fine-grained sediment. Other properties are assigned fixed values consistent with current practice. The quantity of radionuclides released as cavings depends on the volume of eroded material and its activity, which is treated in the same manner as the activity of cuttings (see also Section PA-4.5 and Section PA-6.8.2.1).

Unlike releases from cuttings and cavings, which occur with every modeled borehole intrusion, spalling releases will occur only if pressure in the waste-disposal region exceeds the hydrostatic pressure in the borehole. At lower pressures, below about 8 megapascals (MPa), fluid in the waste-disposal region will not flow toward the borehole. At higher pressures, gas flow toward the borehole may be sufficiently rapid to cause additional solid material to enter the borehole. If spalling occurs, the volume of spalled material will be affected by the physical properties of the waste, such as its tensile strength and particle diameter. The DOE based the parameter values used in the PA on reasonable and conservative assumptions. Since the CCA, a revised conceptual model for the spallings phenomena has been developed (see the CRA-2004, Appendix PA, Section PA-4.6 and Appendix PA, Attachment MASS, Section MASS-16.1.3). Model development, execution, and sensitivity studies necessitated implementing parameter values pertaining to waste characteristics, drilling practices, and physics of the process. The parameter range for particle size was derived by expert elicitation (U.S. Department of Energy 1997).

The quantity of radionuclides released as spalled material depends on the volume of spalled waste and its activity. Because spalling may occur at a greater distance from the borehole than cuttings and cavings, spalled waste is assumed to have the volume-averaged activity of CH-TRU waste, rather than the sampled activities of individual waste streams. The low permeability of the region surrounding the RH-TRU waste means it is isolated from the spallings process and does not contribute to the volume or activity of spalled material (see also Section PA-4.6 and Section PA-6.8.2.2 for more description of the spallings model).

Radionuclides may be released to the accessible environment if repository brine enters the borehole during drilling and flows to the ground surface. The quantity of radionuclides released by direct brine flow depends on the volume of brine reaching the ground surface and the concentration of radionuclides contained in the brine. As with spallings, DBRs will not occur if repository pressure is below the hydrostatic pressure in the borehole. At higher repository pressures, mobile brine present in the repository will flow toward the borehole. If the volume of brine flowing from the repository into the borehole is small, it will not affect the drilling operation, and flow may continue until the driller reaches the base of the evaporite section and installs casing in the borehole (see also Section PA-4.7 and Section PA-6.8.2.3).

Actinides may be mobilized in repository brine in two principal ways:

1. As dissolved species

2. As colloidal species

The solubilities of actinides depend on their oxidation states, with the more reduced forms (for example, III and IV oxidation states) being less soluble than the oxidized forms (V and VI). Conditions within the repository will be strongly reducing because of large quantities of metallic Fe in the steel containers and the waste, and—in the case of plutonium (Pu)—only the lower-solubility oxidation states (Pu(III) and Pu(IV)) will persist. Microbial activity will also help create reducing conditions. Solubilities also vary with pH. The DOE is therefore emplacing MgO in the waste-disposal region to ensure conditions that reduce uncertainty and establish low An solubilities. MgO consumes CO2 and buffers pH, lowering An solubilities in WIPP brines (see Appendix SOTERM-2009 and Appendix MgO-2009). Solubilities in the PA are based on the chemistry of brines that might be present in the waste-disposal region, reactions of these brines with the MgO engineered barrier, and strongly reducing conditions produced by anoxic corrosion of steels and other Fe-based alloys.

The waste contains organic ligands that could increase An solubilities by forming complexes with dissolved An species. However, these organic ligands also form complexes with other dissolved metals, such as magnesium (Mg), calcium (Ca), Fe, lead (Pb), vanadium (V), chromium (Cr), manganese (Mn), and nickel (Ni), that will be present in repository brines due to corrosion of steels and other Fe-based alloys. The CRA-2009 PA speciation and solubility calculations include the effect of organic ligands but not the beneficial effect of competition with Fe, Pb, V, Cr, Mn, and Ni. (Appendix SOTERM-2009, Section SOTERM-2.3.6 and Section SOTERM-4.6, and Brush and Xiong 2005).

Colloidal transport of actinides has been examined, and four types of colloids have been determined to represent the possible behavior at the WIPP. These include microbial colloids, humic substances, An intrinsic colloids, and mineral fragments. Concentrations of An mobilized as these colloidal forms are included in the estimates of total An concentrations used in PA (Appendix SOTERM-2009, Section SOTERM-3.8.1 and Section SOTERM-4.7, and Garner and Leigh 2005).

Long-term releases to the ground surface or groundwater in the Rustler Formation (hereafter referred to as the Rustler) or overlying units may occur after the borehole has been plugged and abandoned. In keeping with regulatory criteria, borehole plugs are assumed to have properties consistent with current practice in the basin. Thus, boreholes are assumed to have concrete plugs emplaced at various locations. Initially, concrete plugs effectively limit fluid flow in the borehole. However, under most circumstances, these plugs cannot be expected to remain fully effective indefinitely. For the purposes of PA, discontinuous borehole plugs above the repository are assumed to degrade 200 years after emplacement. From then on, the borehole is assumed to fill with a silty-sand-like material containing degraded concrete, corrosion products from degraded casing, and material that sloughs into the hole from the walls. Of six possible plugged borehole configurations in the Delaware Basin, three are considered either likely or adequately representative of other possible configurations; one configuration (a two-plug configuration) is explicitly modeled in the flow and transport model (see Section PA-3.7 and Appendix MASS-2009, Section MASS-16.3).

If sufficient brine is available in the repository, and if pressure in the repository is higher than in the overlying units, brine may flow up the borehole following plug degradation. In principle, this brine could flow into any permeable unit or to the ground surface if repository pressure were high enough. For modeling purposes, brine is allowed to flow only into the higher-permeability units and to the surface. Lower-permeability anhydrite and mudstone layers in the Rustler are treated as if they were impermeable to simplify the analysis while maximizing the amount of flow into units where it could potentially contribute to disposal system releases. Model results indicate that essentially all flow occurs into the Culebra, which has been recognized since the early stages of site characterization as the most transmissive unit above the repository and the most likely pathway for subsurface transport (see also the CRA-2004, Chapter 2.0, Section 2.2.1.4.1.2).

Site characterization activities in the units above the Salado have focused on the Culebra. These activities have shown that the direction of groundwater flow in the Culebra varies somewhat regionally, but in the area that overlies the repository, flow is southward. These characterization and modeling activities conducted in the units above the Salado confirm that the Culebra is the most transmissive unit above the Salado. The Culebra is the unit into which actinides are likely to be introduced from long-term flow up an abandoned borehole. Regional variation in the Culebra’s groundwater flow direction is influenced by the transmissivity observed, as well as the lateral (facies) changes in the lithology of the Culebra in the groundwater basin where the WIPP is located. Site characterization activities have provided no evidence of karst groundwater systems in the controlled area, although groundwater flow in the Culebra is affected by the presence of fractures, fracture fillings, and vuggy pore features (see Appendix HYDRO-2009 and the CRA-2004, Chapter 2.0, Section 2.1.3.5). Other laboratory and field activities have focused on the behavior of dissolved and colloidal actinides in the Culebra.

Basin-scale regional modeling of three-dimensional groundwater flow in the units above the Salado demonstrates that it is appropriate, for the purposes of estimating radionuclide transport, to conceptualize the Culebra as a two-dimensional confined aquifer (see the CRA-2004, Chapter 2.0, Section 2.2.1.1). Uncertainty in the flow field is incorporated by using 100 different geostatistically based T fields, each of which is consistent with available head and transmissivity data (Appendix PA-2009, Appendix TFIELD-2009).

Groundwater flow in the Culebra is modeled as a steady-state process, but two mechanisms considered in the PA could affect flow in the future. Potash mining in the McNutt Potash Zone (hereafter referred to as the McNutt) of the Salado, which occurs now in the Delaware Basin outside the controlled area and may continue in the future, could affect flow in the Culebra if subsidence over mined areas causes fracturing or other changes in rock properties (see the CRA-2004, Chapter 6.0, Section 6.3.2.3). Climatic changes during the next 10,000 years may also affect groundwater flow by altering recharge to the Culebra (see the CRA-2004, Chapter 6.0, Section 6.4.9 and the CCA, Appendix CLI).

Consistent with regulatory criteria of 40 CFR § 194.32, mining outside the controlled area is assumed to occur in the near future, and mining within the controlled area is assumed to occur with a probability of 1 in 100 per century (adjusted for the effectiveness of AICs during the first 100 years after closure). Consistent with regulatory guidance, the effects of mine subsidence are incorporated in PA by increasing the transmissivity of the Culebra over the areas identified as mineable by a factor sampled from a uniform distribution between 1 and 1000 (U.S. Environmental Protection Agency 1996a, p. 5229). T fields used in PA are therefore adjusted and steady-state flow fields calculated accordingly; once for mining that occurs only outside the controlled area, and once for mining that occurs both inside and outside the controlled area (Appendix TFIELD-2009, Section 9.0). Mining outside the controlled area is considered in both undisturbed and disturbed repository performance.

The extent to which the climate will change during the next 10,000 years and how such a change will affect groundwater flow in the Culebra are uncertain. Regional three-dimensional modeling of groundwater flow in the units above the Salado indicates that flow velocities in the Culebra may increase by a factor of 1 to 2.25 for reasonably possible future climates (see the CCA, Appendix CLI). This uncertainty is incorporated in PA by scaling the calculated steady-state specific discharge within the Culebra by a sampled parameter within this range.

Field tests have shown that the Culebra is best characterized as a double-porosity medium for estimating contaminant transport in groundwater (see the CRA-2004, Chapter 2.0, Section 2.2.1.4.1.2 and Appendix HYDRO-2009). Groundwater flow and advective transport of dissolved or colloidal species and particles occurs primarily in a small fraction of the rock’s total porosity and corresponds to the porosity of open and interconnected fractures and vugs. Diffusion and slower advective flow occur in the remainder of the porosity, which is associated with the low-permeability dolomite matrix. Transported species, including actinides (if present), will diffuse into this porosity.

Diffusion from the advective porosity into the dolomite matrix will retard An transport through two mechanisms. Physical retardation occurs simply because actinides that diffuse into the matrix are no longer transported with the flowing groundwater. Transport is interrupted until they diffuse back into the advective porosity. In situ tracer tests have demonstrated this phenomenon. Chemical retardation also occurs within the matrix as actinides are sorbed onto dolomite grains. The relationship between sorbed and liquid concentrations is assumed to be linear and reversible. The distribution coefficients (Kds) that characterize the extent to which actinides will sorb on dolomite were based on experimental data (see the CRA-2004, Chapter 6.0, Section 6.4.6.2).

Human intrusion scenarios evaluated in the PA include both single intrusion events and combinations of multiple boreholes. Two different types of boreholes are considered: those that penetrate a pressurized brine reservoir in the underlying Castile Formation (hereafter referred to as the Castile), and those that do not.

The presence of a brine reservoir under the repository is speculative, but on the basis of current information cannot be ruled out. A pressurized brine reservoir was encountered at the WIPP-12 borehole within the controlled area to the north of the disposal region, and other pressurized brine reservoirs associated with regions of deformation in the Castile have been encountered elsewhere in the Delaware Basin (see the CRA-2004, Chapter 2.0, Section 2.2.1.2.2). Based on a geostatistical analysis of the geophysical data of brine encounters in the region, the DOE estimates that there is a 0.08 probability that a random borehole penetrating waste in the WIPP will also penetrate an underlying brine reservoir (see the CCA, Appendix MASS, Attachment 18-6). Upon their review of the CCA, the EPA determined that the DOE should treat this probability as uncertain, ranging from 0.01 to 0.60 in the CCA PAVT. The EPA also required the DOE to modify the assumptions concerning Castile properties to increase the brine reservoir volumes (U.S. Environmental Protection Agency 1998b; Technical Support Document for 194.23: Parameter Justification Report, Section 5). The EPA determined that changing the rock compressibility and porosity of the Castile effectively modified the sampled brine reservoir volume to include the possibility of larger brine reservoir volumes like those encountered by the WIPP-12 borehole.

The primary consequence of penetrating a pressurized reservoir is to provide an additional source of brine beyond that which might flow into the repository from the Salado. Direct releases at the ground surface resulting from the first repository intrusion would be unaffected by additional Castile brine, even if it flowed to the surface, because brine moving straight up a borehole will not significantly mix with waste. However, the presence of Castile brine could significantly increase radionuclide releases in two ways. First, the volume of contaminated brine that could flow to the surface may be greater for a second or subsequent intrusion into a repository that has already been connected by a previous borehole to a Castile reservoir. Second, the volume of contaminated brine that may flow up an abandoned borehole after plug degradation may be greater for combinations of two or more boreholes that intrude the same panel if one of the boreholes penetrates a pressurized reservoir. Both processes are modeled in PA.

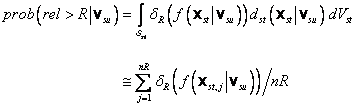

The DOE’s approach to demonstrating continued compliance is the PA, which is based on the criteria indicated in section 194.34. The PA process comprehensively considers the FEPs relevant to disposal system performance (see Appendix SCR-2009). Those FEPs shown by screening analyses to potentially affect performance are included in quantitative calculations using a system of loosely coupled computer models to describe the interaction of the repository with the natural system, both with and without human intrusion. Uncertainty in parameter values is incorporated in the analysis by a Monte Carlo approach, in which multiple simulations (or realizations) are completed using sampled values for the imprecisely known input parameters (see the CRA-2004, Chapter 6.0, Section 6.1.5). Distribution functions characterize the state of knowledge for these parameters, and each realization of the modeling system uses a different set of sampled input values. A sample size of 300 results in 300 different values of each parameter. Thus, there are 300 different sets (vectors) of input parameter values. These 300 vectors were divided among 3 replicates. Quality assurance activities demonstrate that the parameters, software, and analysis used in PA were the result of a rigorous process conducted under controlled conditions (40 CFR § 194.22).

Of the FEPs considered, exploratory drilling for natural resources was identified as the only disruption with sufficient likelihood and consequence of impacting releases from the repository. For each vector of parameters values, 10,000 possible futures (realizations) are simulated, where a single future is defined as a series of intrusion events that occur randomly in space and time (Section PA-2.2). Each of these futures is assumed to have an equal probability of occurring; hence a probability of 0.0001. Cumulative radionuclide releases from the disposal system are calculated for each future, and CCDFs are constructed by sorting the releases from smallest to largest and then summing the probabilities across the future. Mean CCDFs were then computed for the three replicates of sampled parameters (Section PA-2.2).

This section summarizes the results of the CRA-2009 PA and demonstrates that the WIPP continues to comply with the quantitative containment requirements in 40 CFR § 191.13(a). The CRA-2009 PA is different than the original certification PA in the CCA and the PA in the CRA-2004 PABC because it includes additional information, changes, and new data required by 40 CFR § 194.15 recertification application requirements. Table PA-1 details the changes and new information included in this PA.

The results of the CRA-2009 PA demonstrate that the repository continues to comply with the disposal standards. The key metric for regulatory compliance is the mean CCDF. Figure PA-1, which compares the overall mean CCDF for the CRA-2009 PA to the overall mean CCDF for the CRA-2004 PABC, demonstrates two key points. First, the overall mean CCDF lies entirely below the limits specified in section 191.13(a). Thus, the WIPP is in compliance with the containment requirements of Part 191. Second, for any probability, the expected releases in the CRA-2009 PA are only slightly higher than those in the CRA-2004 PABC, primarily because of the increased drilling rate.

Figure PA-1. Overall Mean CCDFs for Total Normalized Releases: CRA-2009 PA and CRA-2004 PABC

Detailed results of the CRA-2009 PA are contained in Section PA-9.0, which describes sensitivity analyses conducted as the final step in the Monte Carlo analysis. These sensitivity analyses indicate the relative importance of each sampled parameter in terms of its contribution to uncertainty in estimating disposal system performance. Analyses also examine the sensitivity of intermediate performance measures to the sampled parameters. Examples of such intermediate performance measures include the quantity of radionuclides released to the accessible environment by any one mechanism (for example, cuttings or DBRs), and other model results that describe conditions of interest, such as disposal region pressure.

Section PA-9.0 presents CCDF distributions for each replication of the analysis, mean CCDFs, and an overall mean CCDF with the 95% confidence interval estimated from the 3 independent mean distributions. All 300 individual CCDFs, as well as the overall mean CCDF determined from the 3 replicates, lie entirely below and to the left of the limits specified in section 191.13(a) (see Figure PA-79). Thus, the WIPP continues to comply with the containment requirements of Part 191. Comparing the results of the 3 replicates indicates that the sample size of 100 in each replicate is sufficient to generate a stable distribution of outcomes (see Figure PA-80). Within the region of regulatory interest (that is, at probabilities greater than 10 -3/104 year [yr]), the mean CCDFs from each replicate are essentially indistinguishable from the overall mean.

As discussed in Section PA-9.1, Section PA-9.2, and Section PA-9.3, examining the normalized releases from cuttings and cavings, spallings, and DBRs provides insight into the relative importance of each release mode’s contribution to the mean CCDF’s location and the compliance determination. Releases from cuttings and cavings dominate the mean CCDF at high probabilities, while DBRs dominate the mean CCDF at low probabilities. Spallings are less important and have very little effect on the location of the mean. Subsurface releases from groundwater transport are less than 10 -6 EPA units and make no contribution to the mean CCDF’s location.

Uncertainties characterized in the natural system and the interaction of waste with the disposal system environment show little variation between the location of the mean CCDFs of the three replicates, providing additional confidence in the compliance determination. The natural and engineered barrier systems of the WIPP provide robust and effective containment of TRU waste even if the repository is penetrated by multiple borehole intrusions.

This section outlines the conceptual structure of the WIPP PA. First, a discussion of the regulatory requirements is given. The requirements of section 191.13 and section 194.34 (summarized in Section PA-2.2.1) lead to the identification of three main PA components:

1. A probabilistic characterization of the likelihood for different futures to occur at the WIPP site over the next 10,000 years

2. A procedure for estimating the radionuclide releases to the accessible environment associated with each possible future that could occur at the WIPP site over the next 10,000 years

3. A probabilistic characterization of the uncertainty in the parameters used to estimate potential releases

The probabilistic methods employed in WIPP PA give rise to the CCDF specified in section 191.13(a) and the distributions specified by 40 CFR § 194.34(b).

The methodology employed in PA derives from the EPA’s standard for the geologic disposal of radioactive waste, Environmental Radiation Protection Standards for the Management and Disposal of Spent Nuclear Fuel, High-Level and Transuranic Radioactive Wastes (Part 191) (U.S. Environmental Protection Agency 1993), which is divided into three subparts. 40 CFR Part 191 Subpart A applies to a disposal facility prior to decommissioning and establishes standards for the annual radiation doses to members of the public from waste management and storage operations. Part 191 Subpart B applies after decommissioning and sets probabilistic limits on cumulative releases of radionuclides to the accessible environment for 10,000 years (section 191.13) and assurance requirements to provide confidence that section 191.13 will be met (40 CFR § 191.14). Part 191 Subpart B also sets limits on radiation doses to members of the public in the accessible environment for 10,000 years of undisturbed repository performance (section 191.15). 40 CFR Part 191 Subpart C limits radioactive contamination of groundwater for 10,000 years after disposal (section 191.24). In this recertification application, the DOE must demonstrate a reasonable expectation that the WIPP will continue to comply with the requirements of Part 191 Subparts B and C.

The following is the central requirement in Part 191 Subpart B, and the primary determinant of the PA methodology (U.S. Environmental Protection Agency 1985, p. 38086).

§ 191.13 Containment Requirements:

(a) Disposal systems for spent nuclear fuel or high-level or transuranic radioactive wastes shall be designed to provide a reasonable expectation, based upon performance assessments, that cumulative releases of radionuclides to the accessible environment for 10,000 years after disposal from all significant processes and events that may affect the disposal system shall:

(1) Have a likelihood of less than one chance in 10 of exceeding the quantities calculated according to Table 1 (Appendix A); and

(2) Have a likelihood of less than one chance in 1,000 of exceeding ten times the quantities calculated according to Table 1 (Appendix A).

(b) Performance assessments need not provide complete assurance that the requirements of 191.13(a) will be met. Because of the long time period involved and the nature of the events and processes of interest, there will inevitably be substantial uncertainties in projecting disposal system performance. Proof of the future performance of a disposal system is not to be had in the ordinary sense of the word in situations that deal with much shorter time frames. Instead, what is required is a reasonable expectation, on the basis of the record before the implementing agency, that compliance with 191.13(a) will be achieved.

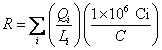

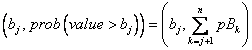

Section 191.13(a) refers to “quantities calculated according to Table 1 (Appendix A),” which means a normalized radionuclide release to the accessible environment based on the type of waste being disposed, the initial waste inventory, and the size of release that may occur (U.S. Environmental Protection Agency 1985, Appendix A). Table 1 of Appendix A specifies allowable releases (i.e., release limits) for individual radionuclides and is reproduced as Table PA-2. The WIPP is a repository for TRU waste, which is defined as “waste containing more than 100 nanocuries of alpha-emitting TRU isotopes, with half-lives greater than twenty years, per gram of waste” (U.S. Environmental Protection Agency 1985, p. 38084). The normalized release R for TRU waste is defined by

(PA.1)

(PA.1)

where Qi is the cumulative release of radionuclide i to the accessible environment during the 10,000-year period following closure of the repository (curies [Ci]), Li is the release limit for radionuclide i given in Table PA-2 (Ci), and C is the amount of TRU waste emplaced in the repository (Ci). In the CRA-2009 PA, C = 2.32 ´ 106 Ci (Leigh and Trone 2005, Section 3). Further, “accessible environment” means (1) the atmosphere, (2) land surfaces, (3) surface waters, (4) oceans, and (5) all of the lithosphere beyond the controlled area. “Controlled area” means (1) a surface location, to be identified by PICs, that encompasses no more than 100 square kilometers (km2) and extends horizontally no more than 5 kilometers (km) in any direction from the outer boundary of the original radioactive waste’s location in a disposal system, and (2) the subsurface underlying such a location (section 191.12).

PAs are the basis for addressing the containment requirements. To help clarify the intent of Part 191, the EPA promulgated 40 CFR Part 194 (2004), Criteria for the Certification and

Table PA-2. Release Limits for the Containment Requirements (U.S. Environmental Protection Agency 1985, Appendix A, Table 1)

|

Radionuclide |

Release Limit Li per 1000 MTHMa or Other Unit of Wasteb |

|

Americium-241 or -243 |

100 |

|

Carbon-14 |

100 |

|

Cesium-135 or -137 |

1,000 |

|

Iodine-129 |

100 |

|

Neptunium-237 |

100 |

|

Pu-238, -239, -240, or -242 |

100 |

|

Radium-226 |

100 |

|

Strontium-90 |

1,000 |

|

Technetium-99 |

10,000 |

|

Thorium (Th) -230 or -232 |

10 |

|

Tin-126 |

1,000 |

|

Uranium (U) -233, -234, -235, -236, or -238 |

100 |

|

Any other alpha-emitting radionuclide with a half-life greater than 20 years |

100 |

|

Any other radionuclide with a half-life greater than 20 years that does not emit alpha particles |

1,000 |

|

a Metric tons of heavy metal (MTHM) exposed to a burnup between 25,000 megawatt-days (MWd) per metric ton of heavy metal (MWd/MTHM) and 40,000 MWd/MTHM. b An amount of TRU wastes containing one million Ci of alpha-emitting TRU radionuclides with half-lives greater than 20 years. |

|

Recertification of the Waste Isolation Pilot Plant’s Compliance with the Part 191 Disposal Regulations. There, an elaboration on the intent of section 191.13 is prescribed.

§ 194.34 Results of performance assessments.

(a) The results of performance assessments shall be assembled into “complementary, cumulative distributions functions” (CCDFs) that represent the probability of exceeding various levels of cumulative release caused by all significant processes and events.

(b) Probability distributions for uncertain disposal system parameter values used in performance assessments shall be developed and documented in any compliance application.

(c) Computational techniques, which draw random samples from across the entire range of the probability distributions developed pursuant to paragraph (b) of this section, shall be used in generating CCDFs and shall be documented in any compliance application.

(d) The number of CCDFs generated shall be large enough such that, at cumulative releases of 1 and 10, the maximum CCDF generated exceeds the 99th percentile of the population of CCDFs with at least a 0.95 probability.

(e) Any compliance application shall display the full range of CCDFs generated.

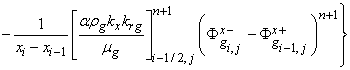

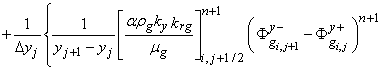

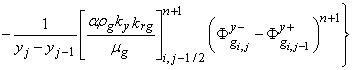

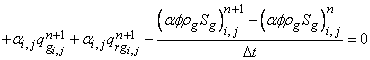

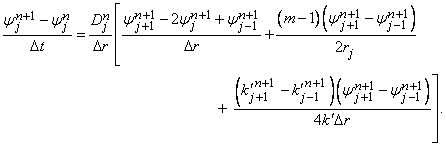

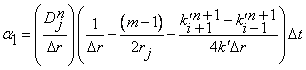

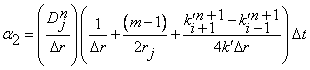

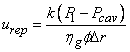

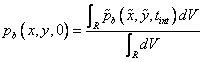

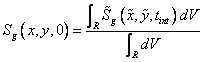

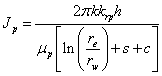

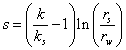

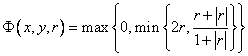

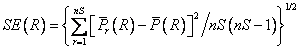

(f) Any compliance application shall provide information which demonstrates that there is at least a 95% level of statistical confidence that the mean of the population of CCDFs meets the containment requirements of § 191.13 of this chapter.